327 Chevy Build

Article by Mark Trotta

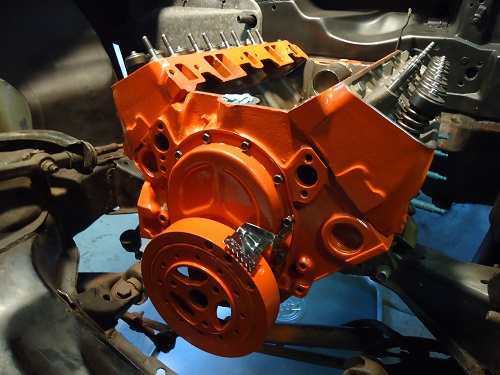

After removing the engine and stripping the block, the next step of the 327 engine overhaul was hauling the bare block to a local machine shop.

To read engine disassembly procedure click here.

Once at the machine shop, the old cam bearings and freeze plugs were removed. The block was then cleaned (hot-tanked), cylinders bored .030" over, and new cam bearings and freeze plugs installed.

While at the machine shop, the crankshaft was cleaned and measured, and connecting rods were reconditioned.

***************************

Bottom End Build

With the block back home and mounted onto the engine stand, the crankshaft was installed, then the connecting rods with the new pistons and rings.

Rebuilding the bottom end included a new Melling oil pump.

Read: 327 Bottom End Build

***************************

In almost every SBC overhaul, the camshaft is replaced along with the lifters. As with all phases of engine rebuilding, care must be taken while installing the camshaft.

***************************

327 Cylinder Heads

The heads on this 1966 Corvette motor were original, casting #3782461. Date codes are J-12-5 and J-20-5 (October 12th and 20th, 1965). These were one of the best flowing factory heads GM had to offer for the small-block.

Cylinder head assembly included checking, measuring, cleaning, re-assembly, and painting.

Lapping valves does not take the place of a valve job, but it does confirm whether or not one is needed.

327 Chevy Build Before and After

Read: SBC Timing Chain, Gears, and Cover

To get paint to stick to a cast-iron engine block and cylinder heads, the metal must be clean and dry.

Read: Spray Paint Engine Block And Parts

Following the cylinder head rebuild was the valve-train assembly, which included installing lifters, push rods, rocker arms, rocker nuts, and rocker balls.

***************************

L75 Small-Block

The 327 engine in this article is from a 1966 Corvette.

It's an L75 motor, which was factory-fitted with a single four-barrel carburetor and rated at 300 horsepower.

Read: How To Polish Aluminum Engine Parts

NOTE: The aluminum valve covers in the above picture are not correct for an L75 engine. Other than that, the motor was all original.

***************************

Related Articles: