9 Ways To Cut Sheet Metal

Article by Mark Trotta

Cutting out damaged sheet metal and trimming patch panels can be done many ways. This article covers the pros and cons of the most popular methods, as well as a few less popular methods.

Air Cut-off Tool

Often referred to as a "wiz wheel", an air-powered cut-off wheel with a 3" cutting wheel is the most often-used tool for panels that are off the body of a car.

If you have a decent-size air compressor, cut-off wheels on sheet metal will work fairly quickly. Do not force the wheel to work faster, because that will ultimately wear out the shaft bearing, overheat the tool, and possibly warp the sheet metal.

Let the air tool do it's job and move slowly along a marked-off line.

Other uses for a cut-off wheel include removing rusty bolts and muffler clamps. By changing the arbor, it becomes a die-grinder. The downside is they're noisy and throw off a shower of sparks.

*****************

Tin Snips

Another way to cut sheet metal is with Aviation Snips. They leave a nice even cut, and are also useful on copper and brass stock.

The only downside to Aviation snips is you need to buy three, a left, a right, and a straight. The handles are usually color coded so you can tell one from another at a glance.

*****************

Hand Nibblers

Hand-held nibblers work fine for smaller patches, but it takes considerable effort on anything heavier than 20 or 22 gauge sheet metal.

*****************

Power Nibblers

If you do a lot of sheet metal work, consider a power nibbler. They can make extremely sharp turns where other tools can't.

Power nibblers save time, particularly on larger patches. Their downside is initial cost, and they also use a lot of air, so a small compressor will be constantly running.

*****************

Electric Cutting Shears

Metal cutting shears are sort of like a pair of electric scissors. They are designed for sheet-metal 14 gauge or thinner.

Cutting shears will cut straight lines smoothly, while removing a 1/4" or so of material where the jaws intersect. They will do slight curves, but don't handle ridges well.

*****************

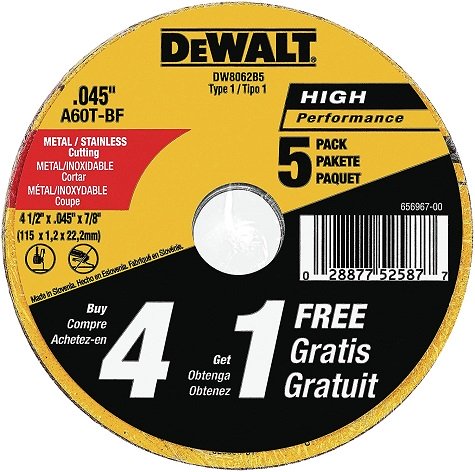

Angle Grinder With Cutoff Disc

For the professional or serious home hobbyist, it's a real time-saver to have a couple of 4-1/2" angle grinders, each fitted with a different type of disc. This saves time and hassle of switching back and forth from one to the other.

Read: Angle Grinder Attachments For Automotive Repair

Cutting speed of an angle grinder is dependant on amperage rating. A 13-amp motor will work faster than a 7-amp motor.

Note - make sure the blade is spinning "up" at the front of the cut or it will try to ride over the top.

*****************

Metal Nibbler Drill Attachment

Metal nibbler drill attachment is designed to cut though thin sheet metal. Works with cordless and electric hand-held drills.

*****************

Hand-Held Hack Saw

Before any of us ever owned an air tool or a power tool, we probably cut metal with a hacksaw. They come in many shapes and sizes, and their main drawback is they're slow and don't fit into tight spots well. You need to put more time and effort into it, but that always makes the finished product a little more personal.

24T vs 32T Blade

To cut sheet metal, a 32T hacksaw blade is best. These are also best for cutting plastic. For the most efficient cut, mount the blade with the teeth facing forward.

*****************

Portable Band Saw

Originally marketed for cutting steel on job sites, portable band saws are very useful for small garage workshops. They cut metal fast and clean, and are quieter than abrasive saws. They work best with 1/4" thick or less metals.

The disadvantage of a portable band saw is most have a 5" opening, which restricts you to cutting pieces that are 5" width or less. So unless you have many small pieces to cut, it's really not the best way to cut sheet metal.

Read: Milwaukee Portaband Saw Review

*****************

Horizontal Band Saw

A horizontal band saw is also great for repetitive cuts, but you're also limited by the neck width. Because they carry a high price tag, they're out of reach for the average DIYer.

Portable band saws can also be bench-mounted or stand-mounted. Many companies, including Swag Offroad, sell tables to convert portable band saws to horizontal table saws.

*****************

What I Use

On a large panel of sheet metal, I'll usually start with cutting shears to cut it into rough shape. Then I'll use hand nibblers and an angle grinder to trim it to exact shape.

Sometimes I'll mark the cut with a black marker, remembering to add about 1/8" or so to the line for trimming.

*****************

Notes and Cautions

Protect your hands from sharp edges - wear gloves.

Clamp the piece of metal you need to cut in a vise securely.

Wear a face shield or safety glasses with side-protectors.

*****************

Read: How To Make A Patch Panel

Read: MIG Weld Sheet Metal