Best Engine Assembly Lube

Article by Mark Trotta

When a freshly rebuilt engine is first fired up, there is a short amount of time before the oil reaches all parts of the motor. Without proper lubrication, heat develops rapidly between moving metal parts, which can cause costly permanent damage.

Properly applied, engine assembly lube eliminates the risk of running metal parts against other metal parts during start-up. It's recommended for use on bearings, gears, cam lobes, cam journals, valve stem tips, pushrod ends, rocker arms, lifter bottoms, etc.

Assembly Lube vs Oil

Conventional motor oil is is designed to work best when it's warm and under low pressure. Under initial engine start-up, it wears off quickly, leaving engine parts exposed to rapid wear.

In contrast, engine assembly lube is designed to work best when cold and under high pressure, which makes it ideal for initial start-up of a freshly rebuilt engine.

While engine oil quickly drips off moving parts, assembly lube is designed to cling onto them. And unlike motor oil, assembly lube stays in place until the engine is started.

Assembly Lube Choices

There are many different types of assembly lube, which will differ in consistency and application and color. Some are thin and pour out easily, some have a consistency similar to honey, and others are just plain gooey. Every engine builder seems to favor one type over another. Here are a few of our favorites:

************************

Permatex Ultra Slick

Designed to allow maximum adhesion to component surfaces during initial start-up, Permatex Ultra Slick meets or exceeds OEM performance specs for engine assembly lubricants.

Excellent for preventing scuffing and galling during start-up, Ultra Slick is a good choice for motors that will not be started for weeks or months.

Texture: Gooey

Color: Dark Red

************************

Liqui Moly Assembly Paste

German made and engineered, Liqui Moly is recommended for bearings, journals, bushings, and wherever metal comes in contact with metal. Active ingredients include zinc sulfide, graphite, fluorides and tungsten disulfide. These are man-made chemicals that are designed to operate at high temperatures.

Liqui Moly costs more than most other assembly lubes, but no other product has a service temperature of -35°C to +450°C. That's minus 95 degrees to 842 degrees Fahrenheit.

Texture: Thick Paste

Color: Black

************************

Lubriplate #105

Recommended for coating all moving parts for motor assembly and rebuilding, Lubricate #105 is much less "gooey" than Ultra Slick and Liqui Moly, but it's thinness makes it easier to spread around in hard to reach areas.

Texture: Pasty

Color: White

Lubriplate 105 is white and waterproof and comes in a 10-ounce tube that squeezes out like white grease. It sticks well once applied, but changes to a liquid upon engine start-up. As the oil starts to circulate throughout the system after warm up, it is dissipated into the oil with no harmful results.

During eighties and early nineties, Lubriplate 105 was much more common, partly because there was no internet yet and auto parts stores sold it. Even though many competitors have popped up, the No. 105 tube is still a good choice for initial engine start-up protection.

NOTE: Lubriplate is not an Extreme Pressure (EP) lubricant like Moly-based lubricants. Because it's lighter in texture than most other assembly lubes, it has many other uses, such as lubing O-rings before assembly, wheel studs and nuts, hood and trunk hinges, firearms, etc.

************************

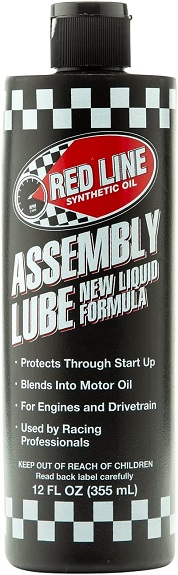

Red Line Assembly Lube

Red Line #80312 is trusted enough to use with 500+ horsepower motor builds. Many top techs in NASCAR, NHRA, and Indy cars recommend it.

Texture: Gooey

Color: Red

Redline is also available in liquid form, which is excellent for valve train parts.

Texture: Liquid

Color: Light Red/Pink

************************

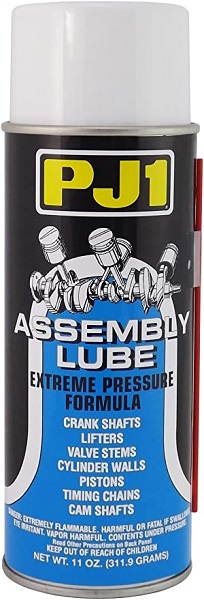

Engine Lube in a Spray Can

Engine assembly lube can be purchased in aerosol spray cans. These are particularly helpful for hard to reach places, such as on and around wrist pins.

Assembly lube in a spray can is convenient for other uses as well.

For example, it adds protection from scoring while press-fitting engine parts.

************************

Assembly Lube Application

When applying, pay particular attention to high friction areas such as cam lobes, valve stem tips, pushrod ends, rocker arms, and lifter bottoms.

Crankcase and bearing surfaces can be coated with an extra amount of assembly grease.

************************

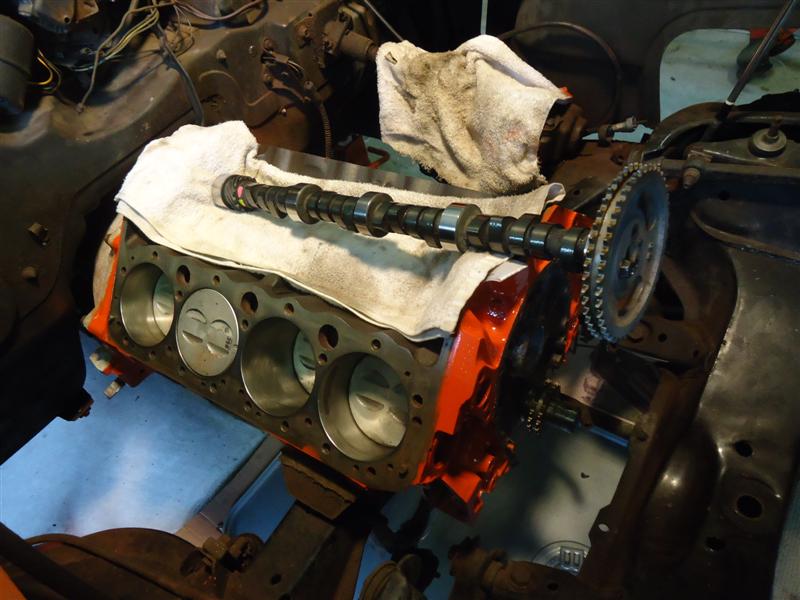

Camshaft Installation

Most cam and lifter kits include a small assembly lube bottle. Coat the cam lobes completely, but not excessively.

Cam bearing journals can be lubed with conventional motor oil.

Engine Start-Up

Regardless of what assembly grease you choose, using a quality break-in oil, and priming the oil system is still important.

Break-In Oil

Lucas SAE 30 break-in oil is a popular choice for flat tappet camshaft break-in.

No moly supplement or additional additives are needed with Lucas break-in oil.

CAUTION: Not recommended for passenger cars with catalytic-equipped emissions controls.

************************

Assembly grease gets the job done for those crucial 10 seconds or before the engine can establish oil pressure and lubricate the hard parts with oil. After the initial startup of the engine, it quickly dissolves at operating temperatures. By then, oil pressure should have built up, which helps flush away the lube away.

Assembly lubes are designed to work in conjunction with engine oil. Once the new engine is broken in, assembly grease is no longer needed, and motor oil can take over.

Most factory manuals recommend running the engine under a moderate load at 1500-2000 RPMs during break-in. Replace engine oil filter shortly after start-up.

Conclusion

Applying a quality assembly lube is just one of many important parts of engine building. There are dozens of brands and many variations, but they all do the same thing - protect your engine internals during the crucial start-up procedure.

Without assembly lube, there's a risk of running internal engine parts metal to metal, which can severely reduce component life. Worst case scenario; your fresh motor seizes up from friction and heat, and becomes an expensive pile of scrap metal. Select an engine assembly lube and use it liberally!

************************

How Much Assembly Lube Do I Need For One Motor?

Generally speaking, a little goes a long way, so a 4oz container is usually enough for a complete engine build.

When replacing the camshaft only, you'll only need a small packet, which often comes with a cam and lifter kit.

************************

Notes and Misc

Although assembly lube is essential for internal engine parts such as crank bearings, rod bearings, camshaft journals, timing gears, and valve stems, engine oil is usually sufficient for pistons and rings--provided engine fire-up is within a day or two of application.

NOTE: It is recommended that a new engine does not sit idle for the first few hundred miles.

NOTE: Synthetic oil is not recommended during break-in.

************************

The oil your classic car left the factory with is not the same oil that you buy today. There are more flat-tappet hydraulic cam failures than ever before, brought about by inferior foreign lifters as well as the removal of ZDDP additives from motor oils.