Corvette CrossFire Engine and Diagnosis

Article by Mark Trotta

For 1982 and 1984, Corvette buyers had no drivetrain options, it was the 350 cubic-inch Crossfire Injection engine (RPO L83). The Crossfire induction system was also available on 1982 and 1983 Z28 Camaros, but only on the 305 cubic-inch motor (RPO LU5). On the Camaro, it provided 20 more horsepower over the carbureted 305 engine.

Featuring two cross-mounted 48mm throttle-body injection units (GM# 17083055), combined total flow was 750 cfm. Each throttle-body fed one bank of cylinders; the right-side throttle body fed the left bank of cylinders and the left-side fed the right bank.

A low-pressure high-volume electric fuel pump was mounted inside the gas tank, which was activated by an electronic computer.

With the help of the Crossfire injection system, engine output for 1982 Corvettes increased to 200 horsepower, peaking at 4,200 rpm, and a torque rating of 283 lb/ft at 2,800 rpm. Although that number seems low by today's standards, it was the highest output for a small-block Chevy in nine years.

Crossfire Myths and Misconceptions

When the Corvette Crossfire engine was introduced, virtually no-one knew about it, save for a handful of trained factory techs.

Due to the complexity of the electronic controls and the special tools needed, engine problems were often misdiagnosed and mishandled. Amateur racers started playing with it like it was a carburetor - which it wasn't. Soon after, the Crossfire Injection system picked up an undeserved bad reputation.

Crossfire Fuel Injectors

Two fuel injectors are used on a Crossfire motor, each opening every time there is a primary ignition pulse. Since two are used, each injector opens every other time a spark plug fires. They are wired to a switched 12 volt ignition and are grounded by the ECM to open them. Required fuel pressure is 9 to 12 psi.

Crossfire Intake Manifold

The reason for peak torque happening at only 2,800 rpm was due to the small ports on the Crossfire aluminum intake manifold - they were about two-thirds the size of the port on the cylinder head. These small ports severely limited performance above 4,000 rpm. GM engineers claimed this was done to have more usable street torque on the bottom end, but Corvette enthusiasts have always debated the validity of this. For those looking for more power, proper porting will yield a solid increase.

The cross-ram intake manifold is designed to quicken the velocity of the air/fuel mixture ratio. The design dates back to 1968, when Mark Donahue dominated the SCCA Trans-Am series with his Penske-owned Z/28 Camaro, powered by a 302ci small-block V8 with dual Holley 4-barrel carburetors.

*********************

Crossfire Engine Diagnosis

Just like a carbureted engine, the 1982/1984 Corvette Crossfire injection system needs the correct amounts of fuel, spark, and air to run properly. Before you start replacing parts, start with the basics.

If you don't know the history of the car, start with an engine tune-up. Check/replace your spark plugs, wires, cap, and rotor. Check/replace the fuel filter and air filters. Engine timing on Crossfire Corvettes is controlled by the computer.

Wix 33482 fuel filter is a direct replacement for AC Delco GF482 and fits 1982 Corvettes, as well as many other GM year, make, and models.

Remove the air filter housing and start the car. Check that both injectors are firing at idle. If not, on the fuse box under the dash on drivers side, there are two fuses for the injectors, injector #1 and injector #2. Both are 3-amp fuses.

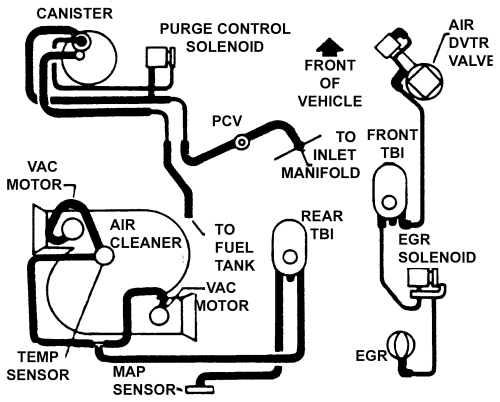

Replace Vacuum Hoses

Although they appear to be Ok, old vacuum lines can cause vacuum leaks. This is a simple task that doesn't cost much.

Fuel Pump Pressure

Many Crossfire issues have ended with fuel pump replacement. The system needs a minimum of 13 to 15 PSI of fuel pressure - any less and it's starving for fuel and won't run right.

Read: 1982 Corvette Fuel System

The ECU (electronic control unit) will only fire the injectors as long as it is getting a tachometer feedback signal from the distributor. Check the white wire that goes to the connection marked "TACH". Also check the harness connectors from the distributor to make sure they are clean and making good contact.

Coolant Temperature Sensor

If you have surging idle or cold start stalling, it may be the coolant temperature sensor. This sensor tells the ECU what temperature the coolant is and the ECU adjusts the mixture accordingly, with other parameters supplied by other sensors. The CTS is located at the front of the intake manifold under the air pump. It has two wires (black and yellow) on the connector that are notorious for breaking. If the wires are broken or intermittent, or if the sensor is bad, it will give the ECU false readings. A new sensor is about $25 and easy to install.

Idle Air Control Motor

A troublesome spot was the Idle Air Control motors (IAC). If one got weak, it would cause an idle control problem. Many inexperienced owners and mechanics would try to adjust the throttle blade angles via the linkage, which made matters worse. If an IAC motor goes bad, it's best to replace them in pairs.

Oil Pressure Switch

In addition to monitoring oil pressure, the oil pressure switch also keeps the fuel pump running after the engine has started. A loose or dirty connection here may cause the fuel pump to randomly stop running. This is because the sensor is designed to shut the fuel pump off if there is a loss of oil pressure.

Clean the contacts on the oil pressure switch that has a brass angle fitting coming off the top of the block, next to the distributor on the driver's side. If you do get the initial squirts and several as you are cranking the engine, but none after it kicks over, then check your oil pressure switch next to the distributor for loose contacts. That has to be working to keep the fuel pump relay engaged.

If the injector continues to supply fuel even after the wires have been removed, it needs to be replaced. When changing injectors, be sure to install ones that have the same resistance as the originals.

Front and rear Crossfire injectors are different from each other (two different OE part numbers) so they should probably not be reversed. While inspecting the injectors, its a good idea to replace both injector O-rings.

*********************

Read: Battery Jump Pack Review

*********************

During engine operation, an oxygen sensor in the exhaust and other sensors continually send signals to the ECU, which then signals each fuel injector, which cycles open or closed to adjust air/fuel mixture. Computerized metering helped boost horsepower and also lowered emissions. This early ECU was capable of 60 calculations per second - today's ECU's are capable of several thousands of calculations per second.

AC Delco AFS21 oxygen sensor fits 1982 Corvettes as well as many other GM year, make, and models.

ECM Swap

I've read on forums that an ECU from 1988 through 1992 TBI equipped Chevy V8's (#1227746) may be used in place of the earlier, original ECUs (the 1982 ECU uses service number 1225550). This would require adapting the later ECU connectors to the original harness.

NOTE: ECU's produced after 1982 are half the size of earlier ones.

Performance Upgrades

Several companies offer performance upgrades for Corvette Crossfire Engine, particularly intake manifolds, which have bigger ports than stock and really "wake up" the motor.

I'm not sure if Renegade Crossfire intake manifolds are still being produced, but good used ones pop up from time to time.

Other upgrades include free-flow air filters, lower temperature thermostats and cooling fan switches, as well as performance ECM chips.

*********************

Conclusion

The Corvette Crossfire engine is historically significant because it bridged the gap between yesterdays carburetors and today's modern fuel injection systems.

Crossfire-equipped models are unique because of their limited production, and over the years have slowly gained acceptance with classic Corvette enthusiasts.

To ensure trouble-free service from yours, drive your car at least once a month and use name-brand premium fuel (non-Ethanol is preferred). This should eliminate the need for cleaners and prevent moisture from contaminating the fuel system.

*********************

Related Articles: