Garage Air Compressor Review

Article by Mark Trotta

Automotive repair and restoration requires a bigger air compressor than ordinary workshop needs. This is to allow the use of air tools, which deliver higher torque and are more powerful than electric tools.

CFM Requirements For Air Tools

To determine the best air compressor for your needs, consider the air tools you'll be using. All air tools have a rating of the flow and pressure that it needs to operate.

Common automotive air tool requirements:

- Cut-Off Tool: 4 to 10 CFM

- Angle Disc Grinder: 5 to 8 CFM

- Dual-Action Sander: 11 to 13 CFM

- 1/4" Ratchet: 2.5 to 3.5 CFM

- 3/8" Ratchet: 4.5 to 5 CFM

- Air Hammer: 6 to 11 CFM

- Mini Die Grinder: 4 to 6 CFM

Air Flow vs Air Pressure

Compressors are rated by SCFM (standard cubic feet per minute), which is the amount of air it can deliver when running constantly. Flow and pressure are inversely proportional, so as the pressure goes up, the flow will go down.

Air Compressor Ratings

Air tools are often rated as 'Average CFM' which is based on a 25% duty cycle (15 seconds out of a minute). If you will be using an air tool on a continuous basis, such as an orbital sander or die grinder, multiply the Average CFM by four. This will give you a realistic, continuous CFM rating for the tool.

Look at the "delivered" CFM rating, not the CFM "displaced" rating.

Horsepower Rating

The more horsepower (and larger air tank) a compressor has, the better it will do at higher PSI settings. This would include die grinders and air hammers.

Oil-Lubricated vs Oil-Free

An oil-lubricated cast-iron compressor will last a longer time than an oil-free unit. If you're running mostly air tools, and not spray painting, oil-lubricated is a good choice.

When painting cars with a compressor and spray gun, you need to take preventative steps to eliminate possible oil contamination. With oil-free motors. there is less risk of oil contamination, but they do run louder.

*************************

Single-Stage vs Two-Stage Compressors

Single-stage units are smaller and louder, cycle more often, and are less expensive. Two-stage compressors are not really necessary for home garage, but they are quieter, cycle less frequently, and deliver lots of continuous pressure. Most of the noise is a low frequency thumping sound.

For a low to medium use, single-stage air compressors work well. Most are 110v and can be plugged right into the wall. If you are going to use it for cut-off wheels and grinders that's fine, but if your planning on sandblasting with a pressure blaster it will mostly likely not keep up.

Large two-stage compressors are for medium and heavy use. If you are constantly using air tools, this is what you need. They are built to run more often and keep higher pressure. If you're serious about automotive restoration, consider a 220v unit with a dual-stage motor. Pay a qualified electrician to run a 220v outlet into the garage, especially if you plan to weld anything more than sheet metal.

*************************

Currently, my garage air compressor is a Campbell-Hausfeld 26-gallon, 220v unit. The motor is cast iron and delivers 5.5 CFM at 90 PSI. It is oil-lubricated and rated at three running horsepower.

Shop: Campbell Hausfeld Air Compressor

When I bought this compressor, I placed it next to my workbench for convenience, then had an electrician wire in a 220 volt outlet. In hindsight, this was not a great place because it's gotten louder with age and use. So, now I slip on hearing protection while it's running.

In the 15+ years I've owned it, the C-H compressor has handled all my garage needs, including a lot of automotive sheet metal work (air hammer, DA sander, etc).

Vertical vs Horizontal Compressors

Horizontal tanks will fill quicker, but the motor will cycle on and off more often with prolonged use. If you're using a die-grinder or other constant-duty air tool, they'll run longer and may overheat the motor.

Generally speaking, air compressors that have vertical tanks are offered in larger sizes and take up less floor space, but they are not as easy to move around, if that's a factor.

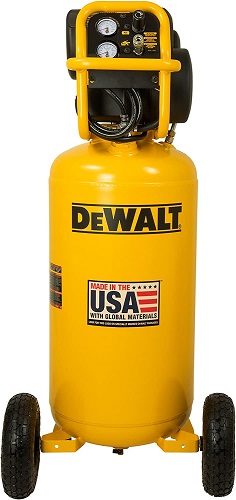

This 27-gallon vertical air compressor by Dewalt is oil-free and delivers 5.1 SCFM at 90 PSI. Height is 50 1/2".

Shop: Dewalt Vertical Air Compressor

*************************

U.S. Brands vs Chinese Brands

Think about five or ten years from now, if your compressor stops working, where can it be fixed? Will you be able to get parts? The advantage here goes to American-based companies, who are established and have service centers in every major city.

*************************

Air Compressor Oil

Depending on usage, compressor oil should be changed once a year. Since compressor oil has additives that are not necessarily found in automobile oil or other oils, only use oil that is clearly labeled as such. Conversely, the additives that are in other types of oils may damage your air compressor.

Air Hoses and Fittings

The most common air hose is 3/8" rubber. These are fine for a single or two-car garages. For painting, a larger 1/2" air hose will give more volume. For a larger shop, consider permanently installed rigid air lines.

Air hoses and tools connect with quick-disconnect couplings. These fittings come in many styles, and they connect the female end on the hose to the male end on the tool. Use Teflon tape on the male fittings for airtight joints.

Air Compressor For Automotive Painting

Smaller compressors will have more trouble with moisture buildup than larger ones. Any restriction in the air line reduces air flow. This is a major concern if you're considering painting a car yourself. A paint gun has a higher duty cycle than an impact wrench or an air ratchet, so the amount of air used is higher.

*************************

Notes and Misc

Your compressor needs air flow around it to prevent overheating. Avoid enclosed areas such as under workbenches.

*************************

Related Articles:

Best Spray Gun For Automotive Restoration

Best HVLP System For Automotive

Tools Needed For Automotive Restoration

Set Up Garage Workshop

Replace Rusty Floor Panels