Rebuild Wheel Cylinders

Article by Mark Trotta

After decades of use, the rubber boots and spring cups in wheel cylinders wear out, allowing brake fluid to leak and drip down onto the brake shoes, diminishing stopping power. As the system gradually loses fluid, a complete loss of braking is possible.

Rebuild or Replace?

Most, but not all, wheel cylinders can be rebuilt. Here's three reasons why yours may not be:

Rebuild kits are not available. This is rarely a problem with classic American cars and trucks. Rebuild kits are generally available from dozens of aftermarket suppliers.

The housing is damaged. This would include badly stripped threads, a broken bleeder screw, or if the housing was cracked.

The bores have deep grooves. A badly pitted bore may cause a piston to stick and allow brake fluid to leak.

Rebuild/Replace One or Both?

Wheel cylinders should be rebuilt or replaced in pairs. Even if only one is leaking, the other one is probably not far off from leaking as well. For safety's sake, rebuild or replace both sides at the same time.

If you find that only one is rebuildable, it's OK to rebuild the one and replace the other with a new cylinder.

Wheel Cylinder Rebuild Kits

Once you decide to rebuild your old wheel cylinders, you'll need to obtain rebuild kits for your year, make, and model vehicle. Although once a common auto parts store item, rebuild kits today are easily found online. You could try a local NAPA store, as they're usually better stocked than others.

***********************

Remove Wheel Cylinder From Vehicle

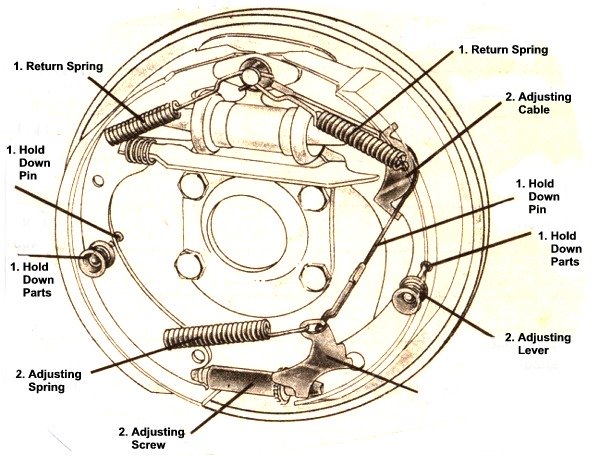

If you haven't done so already, jack up the vehicle, place jack stands under the frame, then remove the tires and brake drums. The brake shoes may have to be removed.

Read: Drum Brake Tools

Before trying to remove, spray the mounting bolts and brake line fittings with WD-40 or similar penetrant. Let it soak so it has time to work. The longer you let is soak the better it works. Sliding a drip tray or piece of cardboard underneath will catch any overflow and brake fluid.

Flare nut wrenches, also called line wrenches, were designed to remove steel brake lines and other hydraulic fittings. A standard wrench may work, but you stand a chance of stripping the fitting.

After loosening, but before taking the fitting off, remove the two mounting bolts that hold the cylinder in place. Then unthread the fitting by hand and remove the wheel cylinder. This is a precautionary measure to prevent damaging the steel lines.

Once the fitting is off, brake fluid will start running out. Have a drip pan or plastic tray ready. To prevent the line from leaking, cover the end of the line with a suitable plug.

Wheel Cylinder Disassembly

Once off the vehicle, it's time for disassembly and inspection. The outer dust boots usually pry off easily but may rip during the process. New ones will come with a rebuild kit.

***********************

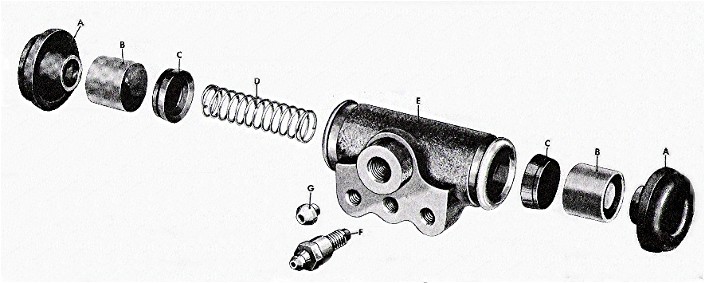

Dust Boot - Piston - Spring Cup - *Spring* - Spring Cup - Piston - Dust Boot

***********************

The pistons inside old wheel cylinders are often stubborn. Try shooting compressed air into the line fitting.

CAUTION: Hold both ends of the cylinder in a rag before blowing compressed air in, or the pistons will fly across the garage!

If compressed air doesn't unstick them, stand the cylinder upright, spray with penetrating fluid, and let soak overnight.

TIP: Take pictures during the removal and installation process.

Pushing out the old piston with a socket.

***********************

Inspection

After disassembly and cleaning with brake parts cleaner, look inside the bore. Run a fingernail inside the bore--does it catch? A smooth bore surface with a light amount of pitting can usually be honed out.

A slight amount of pitting on the piston bore surface is Ok, but if there are any deep nicks or grooves, it's best to replace.

NOTE: On hard-to-find wheel cylinders that are badly damaged, bore surfaces can be renewed by re-sleeving. This is a specialty service that few machine shops still do, and would likely require shipping (and waiting).

***********************

Wheel Cylinder Honing

If no nicks are found, the next step is to hone and polish the bore to a fine finish. The purpose of honing is to allow the rubber cylinder cup to make a good seal.

There are several ways to accomplish this. The most popular method is to use a brake cylinder honing tool and a hand-held electric drill.

Most cylinder hones come with 220 grit stones, which is a little coarse for a final finish. They could take off too much metal and leave a rough finish.

If the bore is only glazed, consider using finer 600 grit stones or 600 grit paper.

***********************

Honing Tips

Use a variable speed drill at low speed using brake fluid as a lubricant. Run the honing tool the full length of the bore in a gradual back and forth motion.

Run the hone long enough to smooth out the bore, but be careful not to over-hone.

When done, wipe out the cylinder (brake parts cleaner and shop towels) and look inside to see if all pits and corrosion are gone. Repeat the honing process until the bore is smooth and free of scratches. Clean the bore and remove all traces of the hone grit, then blow dry with compressed air.

Honing Without A Drill

Another way to hone wheel cylinders is by hand, or more accurately, by finger. Wrap a piece of emery cloth around a finger and have at it. Switch from coarse grit to medium grit and then to fine.

A smooth bore means a tight seal with less chance of leakage.

***********************

Reassembly

Check your rebuild kit and make sure the cups are the same size as the old ones. Pour a little clean brake fluid into a container, and coat the inside of the bore with brake fluid.

First, the spring goes into the center of the bore, then the spring cups get placed on either end (flat side out). The spring will fit into the recess on the back of the spring cup.

Place the piston into the bore and rotate it back and forth several times to coat it. Use the piston to push the rubber cup further into the cylinder.

Install Rubber Dust Boots

Installing the rubber dust boot on the metal piston can be tricky. You can rip the new rubber with a small screwdriver trying seat the dust boot around the lip.

Assembly Order

First the spring, then spring cups (each side), pistons (each side), dust boots (each side)

TIP: Use an appropriate-sized socket and slip the dust boot over the width of the piston (see picture below). Once it's installed, twist it back and forth a couple of times to make sure it's seated all the way around.

Now re-install the bleeder screw, you can use a little anti-seize if you'd like.

Install Wheel Cylinder Back On Vehicle

Mount the rebuilt wheel cylinder onto the backing plate and hand-tighten the mounting bolts leaving the cylinder loose. First, hand-tighten the brake line fitting into the cylinder, then tighten the mounting bolts, then tighten the fitting.

***********************

Brake Fluid

A fresh-rebuilt wheel cylinder with a smooth bore should last as long as the original one did. But remember, similar to engine oil being changed, brake fluid also needs to be changed (much less often). Listed in every car's owners manual shows recommended brake fluid replacement intervals.

Read: Best Brake Fluid For Classic Cars

***********************

Related Articles:

Disc and Drum Brake Restoration

Drum Brake Tools

Best Oil for Classic Cars

Tools Needed For Automotive Restoration