Gen One Small Block Chevy Build

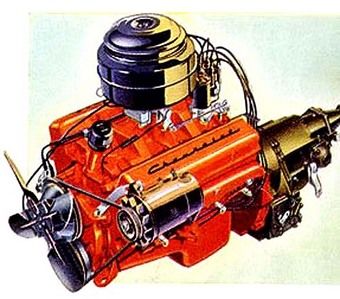

Without question, the most common engine found in street rods and muscle cars is the small-block Chevy V8. They are easy to repair, easy to upgrade, and availability of factory and aftermarket performance parts is second to none!

A Little History

Introduced in 1955, Chevy's small-block V8 was an instant hit with hot rodders. The first SBC had a 265 cubic-inch displacement, bored out to 283ci in 1957.

Read: Chevy Small-Block History 1955-1959

Read: Chevy Small-Block History 1960-1964

Early blocks had an oil filler tube in front of the intake manifold. There was no PCV system, instead, there was a draft tube in the lifter galley. Up until the late sixties, small block valve covers had no holes for breather caps or PCV valves.

Read: Chevy Small-Block History 1965-1969

*****************************

327 Small-Block Chevy

In 1962, the 283 was bored and stroked to 327 cubic-inches. This was the first 4" bore small-block.

327 Chevy Articles:

327 Engine Build

327 Disassembly

327 Bottom End

327 Cylinder Head Assembly

327 Camshaft Installation

327 Timing Chain Installation

*****************************

350 Small-Block Chevy

An increase of piston stroke gave us the 350ci small-block in 1967. This is the most common size SBC. Other first-generation engine sizes are 302, 400, 307, 287, 262, and 305.

*****************************

Journal Size

In 1968, the 327 Chevy small-block was updated with larger diameter crankshaft and connecting rod journals. The main-journal size increased from 2.30" to 2.45". The rod-journal size increased from a 2.00" diameter to a 2.10" diameter, and the connecting rods were now heavier and used 3/8" diameter cap-bolts versus the smaller journal 11/32" diameter.

*****************************

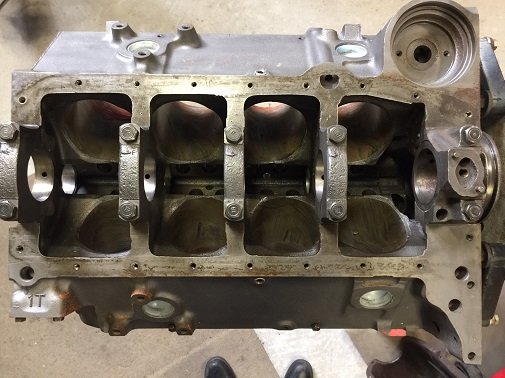

2-Bolt vs 4-Bolt Block

Chevy 350 small-blocks were made with either 2-bolt or 4-bolt main bearing caps. The center-three main caps in the 4-bolt block had two additional bolts which were supported by the addition of heavier crankcase main-web bulkheads.

There was a tech article several years back where an engine builder tested a 2-bolt block to see how much power it would take before main cap flex. The horsepower level was near 600 before any main cap movement was detected.

If you're looking to build a healthy street motor, there's nothing wrong with a 2-bolt main block. But if your small-block Chevy build includes a high revving motor (over 6,000 rpm) and 500+ horsepower, and 4-bolt block is recommended.

*****************************

Was There A Factory 4-Bolt 327 ?

No 283 or 327 Chevy block ever left the factory with four-bolt main caps, but they can certainly be added. Again, this is only required if your engine's making serious horsepower (500+) at very high revs (over 6,000 rpm).

Before doing this, consider selling your vintage block to a restorer and building a 350ci motor.

*****************************

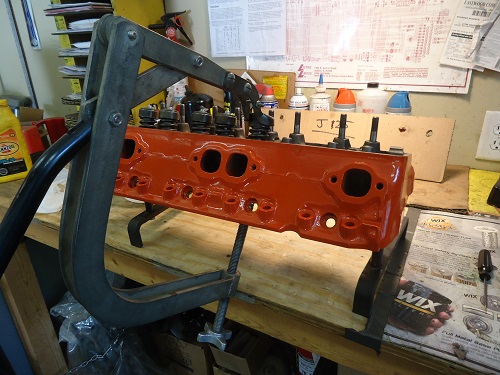

Gen-1 Small-Block Chevy Heads

Early Chevy small-block cylinder heads did not have accessory mounting holes on the ends of the head. Except for some early truck applications, it was not until 1969 that all small-block cylinders had factory-equipped accessory holes.

Read: Best Heads For Gen-1 Small-Block Chevy

*****************************

Original LT-1 Chevy V8

The 1970 350 LT-1 motor was the highest horsepower version of Gen-One small-block Chevys. Power output was 370-horsepower in the Corvette, and 360-horsepower in the Camaro Z/28. The LT-1 featured a solid lifter cam, 11:1 compression, a 780cfm Holley four-barrel carburetor, and aluminum intake manifold.

Even today, 50 years later, engine builders will start with the specs of an first-Gen LT1 and then customize it to their personal requirements.

*****************************

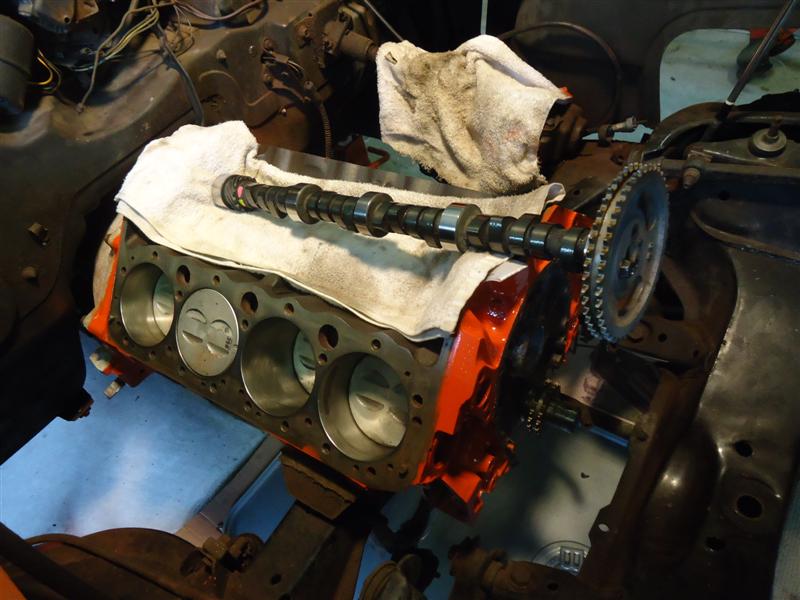

SBC Camshaft Selection

In almost every small-block Chevy build, the camshaft is replaced along with the lifters. Selecting a cam usually involves a compromise between low-end and high-end power, but you don't need a wild camshaft to build a strong-running V8 engine.

Back in the day, Wade Owens of Cape Girardeau, Missouri, ran a 283ci motor in a 1966 Chevelle, and competed successfully in NHRA's Stock Eliminator class. Duration on his cam was about 258/260 degrees at 0.050 inch, and lift for this engine combination is rules-limited to 0.399 inch, measured at the retainer.

With this relatively mild camshaft, Wade's Chevelle consistently ran in the mid-11s, which was at or under the national Stock Eliminator class record.

Read: Camshaft Selection Guide

*****************************

SBC Camshaft Replacement

Replacing a small-block cam with the motor in the car requires a few more steps than when sitting on an engine stand. As with all phases of engine assembly, care must be taken while installing a camshaft.

*****************************

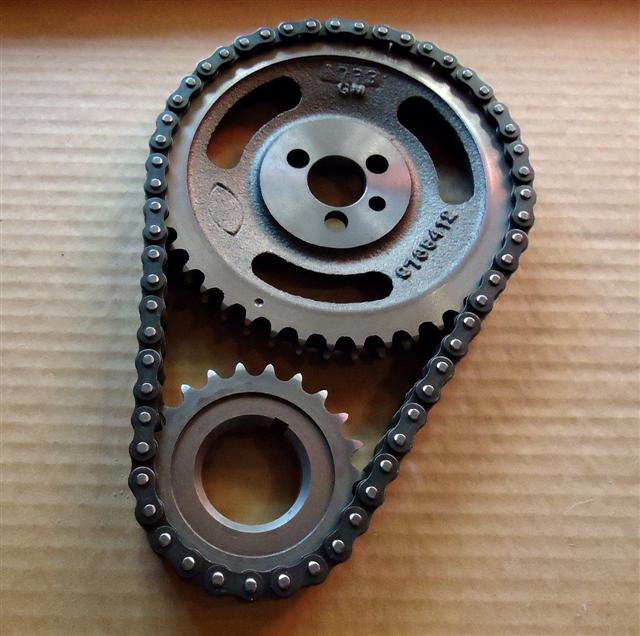

SBC Timing Chain and Gears

Just like everything else for your gen-one small-block, there's a never-ending choice of timing chain and gear kits.

Read: SBC Timing Chain, Gears, and Cover

*****************************

Hydraulic Lifters

On first generation small-block Chevy engines, lifters were either hydraulic flat-tappet or solid flat-tappet, with hydraulic roller and solid roller designs available in the aftermarket. The hydraulic flat-tappet lifter is the most commonly used, having quiet operation and requiring no adjustment once installed correctly. They work well in both stock and modified engines to about 6,500 rpm.

Mechanical Lifters

Mechanical (solid flat-tappet) lifters are generally used in applications where very high RPM's (7,000 rpm or more) are needed. At idle, they will make a slight ticking sound, which is normal. They also need periodic adjustment.

*****************************

SBC Valvetrain

Small-block Chevy valve-train assembly includes lifters, push rods, rocker arms, rocker nuts, and rocker balls. All Gen 1 small blocks use the same valve timing procedure, but there are several sizes of balancers and timing pointers.

Read: SBC Valve-Train Assembly

All Gen-1 SBC Chevy's use firing order: 1-8-4-3-6-5-7-2

*****************************

Vortec Heads (Center-Bolt)

During the production year of 1986, new aluminum heads brought a 40-pound weight savings and a five horsepower output improvement. Compression was slightly boosted from 9.0:1 to 9.5:1, and they had better flow at lower lift than earlier heads.

To improve intake gasket sealing, the mounting bolts were relocated to the valve cover center-line. These four bolts place uniform sealing pressure on the cylinder head mounting flange.

Vortec heads were first offered on the 1986 Corvette, and were the first to have the center-bolt valve covers. Starting in 1987, all Chevy V8's were fitted with either cast iron or aluminum Vortec heads.

Can I Put Vortec Heads On An Early Small Block?

Vortec heads have taller intake ports than earlier small-block heads. They'll bolt up to earlier blocks, but a later intake manifold needs to be fitted.

*****************************

"The world's best cam combined with a poor set of heads will produce an engine that's a dog. But bolt on a set of great heads even with a poor cam, and that engine will still make great power." - John Lingenfelter

*****************************

One-Piece Rear Main Seal

In 1986, the two-piece rear main seal used from 1955 was replaced with a one-piece unit. Displacement of the block was now cast into the block next to the casting number.

*****************************

Classic Car Engine Oil

The 10W30 oil your car left the factory with is not the same 10W30 that you buy today. There are more flat-tappet hydraulic cam failures than ever before, brought about by inferior foreign lifters, as well as the removal of ZDDP additives from motor oils.

Read: Best Oil for Classic Cars

Break-In Oil

Break-in Oil is loaded with anti galling compounds, such as zinc. It does a better job that just adding an additive to regular oil, particularly in the lifter to cam lobe areas.

Lucas 10631 SAE 30 is a high-zinc break-in oil used for flat tappet camshaft break-in. No moly supplement or additional additives are needed with this oil.

NOTE: Not recommended for passenger cars with catalytic-equipped emissions controls.

*****************************

SBC Crate Engine

Although not seen in a new car since 2004, the Gen I Small Block is still in production by a GM subsidiary in Mexico. They are sold under GM's crate engine program and still very popular for replacement and racing/hot rodding.

NOTE: There have been many discrepancies found on crate engines, such as different sized pistons in the same block. For any serious performance, it is best to disassemble the motor and check all parts and clearances.

*****************************

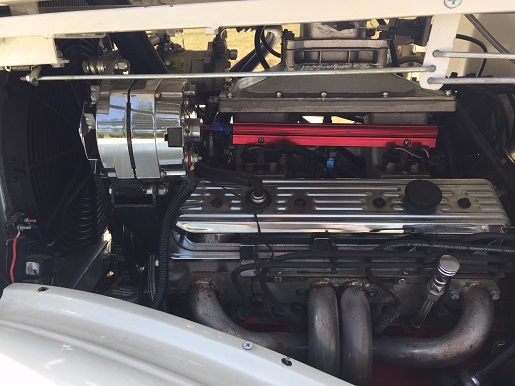

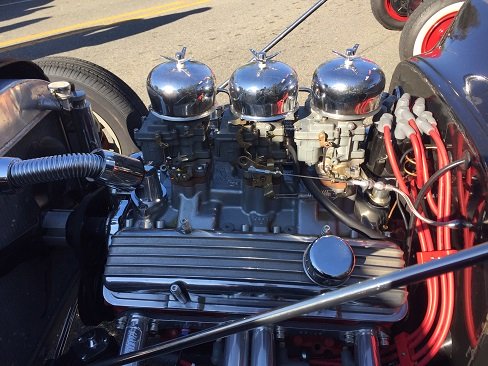

Hot Rods, Jeeps, And Kit Cars

Because of their relatively light weight and compact size, small-block Chevy V8's are often seen in other-than-Chevy cars and trucks. They became popular engine swap choices for CJ Jeeps, Hot Rods, T-Buckets, and many kit cars.

Read: Engine Swap Basics

*****************************

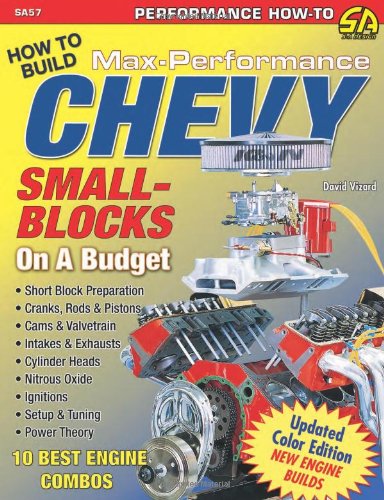

Best Small-Block Chevy Book

Author David Vizard is an authority on V8 Chevy engine building. I've read this book cover to cover several times!

Shop: Chevy Small-Block Book

*****************************

Articles of Interest:

1970 Chevelle Restoration

Old School Small-Block Chevy Build

Best Engine Assembly Lube

Best Tool For Cylinder Head Work