Tools Needed For An Engine Build

Article by Mark Trotta

Once you've decided to rebuild your old car's engine, you'll want to make a plan and a budget. And chances are, you'll be buying a few new tools. In addition to basic hand tools, there'll be some specialty tools needed.

*****************************

Gasket Scraper

Aside from scraping surfaces clean before new gaskets are installed, gasket scrapers are also used to remove old gaskets.

They're also useful to help remove oil pans, valve covers, and timing chain covers without damaging the thin sheet metal.

*****************************

Valvetrain Organizer Tray

If you're rebuilding a V8, you've got 16 lifters, 16 pushrods, and 16 rocker arms. If it's a Chevy V8, there's also 16 rocker balls and 16 locknuts. That's a lot of stuff to keep track of.

Get yourself a Valvetrain Organizer Tray.

Valve Spring Compressor

Depending on whether or not you're rebuilding the cylinder heads yourself or farming them out, a valve spring compressor is needed for removing and installing the valves.

*****************************

Engine Measuring Tools

To properly rebuild an engine, you first need to accurately inspect and measure the old/worn parts. Most of us are more mechanics than machinists, but the need arises during an engine build to precisely measure wear and play.

Measuring tools will include a digital caliper, micrometer(s), dial indicator, dial bore gauge, and feeler gauge. Not only is it important to have quality measuring equipment, you also need to learn how to use these tools correctly.

Dial Test Indicator (DTI)

Having a dial test indicator allows you to check end play, run-out, up-and-down movement, and many others. Most have increments of .001" on a 0" to 1" scale. They can be mounted by clamp or magnetic base.

Engine clearances are crucial, and learning to correctly read precision instruments takes some time. Experienced mechanics always double-check their specs. First-time builders should measure a dozen times (or more) before trusting their readings.

Dial Bore Gauge

To accurately measure the inside diameter of a cylinder, a bore gauge is needed. The one in my workshop has a range of two to six inches, a depth of six inches, and the round dial has .001" increments.

Shop: Dial Bore Gauge

Dial vs Digital Caliper

Here's a link to an overview of vernier, dial, and digital calipers, along with recommendations for the best digital caliper.

Read: Best Digital Caliper For Engine Building

Remember that calipers, micrometers, dial indicators, and dial bore gauges are precision measurements, and need to be treated as such. For consistent and reliable results, keep them clean and out of harm's way.

Feeler Gauge

A feeler gauge, or gap gauge, is made up of thin metal blades. Each blade is a different width of precise thickness, and will be marked in either thousandths of an inch, or millimeters, or both. They are needed for checking valve tolerances, ignition point gaps and other critical measurements.

Shop: Feeler Gauge

Feeler gauge blades usually range from .0015" to .035" (.038 to .889mm). Long feeler gauges may be needed for valve adjustments on some engines.

*****************************

Piston Ring Expander

A piston ring expander is a very inexpensive tool. Don't be tempted to install rings into the piston grooves by hand. Piston rings can get deformed by the twisting action, which may cause sealing problems.

Shop: Piston Ring Pliers

Piston Ring Compressor

To install pistons and rings back into the cylinders, a piston ring installation tool is needed. A clamp-style ring compressor is the least expensive style, but consider investing in a piston ring installer set. Most sets includes five or six popular sizes that you can use for other engine projects.

Shop: Piston Ring Compressor Set

*****************************

Torque Wrench (Foot-Pounds)

For those who haven't used a 'click-style' torque wrench before, you set the desired value on the handle scale, then begin tightening the fastener. When the preset torque value is reached, the wrench will emit a "click" that will be heard and felt.

Shop: 1/2" Torque Wrench (10-150 ft/lbs)

A 1/2" drive torque wrench will generally cover your needs up to 150 foot/pounds. It is recommended to torque bolts in increments; example, first pass 20 ft/lbs, then 40 ft/lbs, then 60 ft/lbs, etc. until desired torque value is reached.

Stay away from beam-style torque wrenches. Most are inaccurate, and all of them hard to read while you're using it.

Torque Wrench (Inch-Pounds)

On the lower end of the scale are 1/4" drive torque wrenches. These are nice to have for things like timing cover bolts, which everybody seems to over-tighten!

Shop: 1/4" Torque Wrench (20-200 in/lbs)

EXAMPLE: Timing chain cover bolts on Gen-One small-block Chevys require only 7 to 9 lb/ft of torque, no more. It's not possible to do that with a 1/2" drive torque wrench.

*****************************

Tap and Die Set

Going hand-in-hand with a torque wrench is a tap and die set. Why? Because you cannot correctly torque down bolts if threads are dirty - you'll get a false reading.

Read: Clean and Tap Bolt Threads

Aside from cleaning threads, dies can also make threads. With proper technique and lubricant, they will cut mild carbon, alloy steel, and cast iron. They also work on aluminum, brass, and bronze.

*****************************

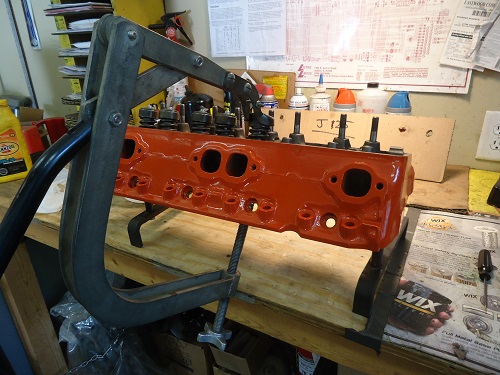

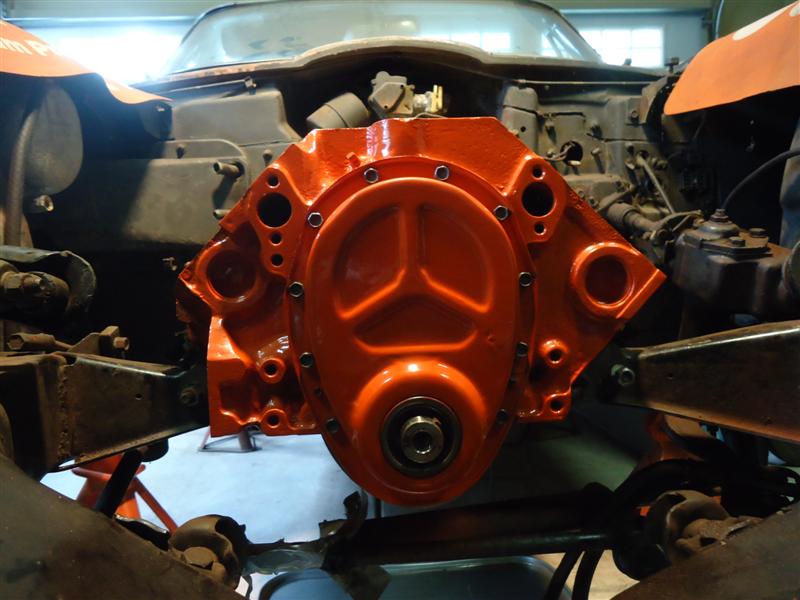

Engine Stand

Technically, you don't need an engine stand, but they sure do make things easier. The only provision here is to make sure it can safely handle the weight of your motor.

Shop: Heavy-Duty Engine Stand

An engine stand must be two things: sturdy and stable. You can't have too heavy an engine stand.

Engine Hoist

Chances are you'll need an engine hoist twice; once to remove, and once to install. Inquire at a local auto parts store or an equipment rental store. Generally they offer two-day rentals, but you must leave a deposit, usually with a credit card.

I've done several motor pulls and have always rented one from a local auto parts store. I never considered buying a hoist, because even disassembled, they take up more space than I have to spare in my garage.

*****************************

Flex Shaft Rotary Tool

Electric rotary grinders are well-suited for automotive head work, such as porting, port matching, and removing casting flash.

Read: Best Tool For Cylinder Head Work

*****************************

Hand Tools Needed For Motor Overhaul

- Sockets, ratchets, and extensions in 1/4", 3/8", and 1/2" drive

- Shallow and deep sockets from 1/4" to 1"

- Wrenches: open-end and combination, from 7/16" to 1"

- Screwdriver set

Read: Best Automotive Hand Tools